Hydrogen Automotive Applications

equipped with fittings from STÖHR ARMATUREN

The industry today

Electro-mobility is currently the most popular solution to the greenhouse gas emissions caused by heavy traffic – and hydrogen is just one of its facets. The potential of fuel cell technology is beyond question, and hydrogen plays a major role in the global discussion on how to reach climate targets.

Fuel cell technology is an integral part of the powertrain strategy of most truck OEMs. The advantages are clear: zero emissions, long ranges and short tanking times, plus a wide range of applications from cars to buses, large commercial vehicles and stationary applications.

Another bridging solution under evaluation is hydrogen combustion engine technology – a robust solution that has the potential to become more rapidly available.

Green energy and future needs

A hydrogen cycle is an effective way of decarbonising heavy traffic and achieving emission-free mobility. ‘Green’ hydrogen is produced using electricity from renewable energy sources (water, sun and wind) and is therefore climate-friendly and practically emission-free.

Future fuel-cell-powered vehicles will be part of a hydrogen ecosystem. Hydrogen will be stored in containers with several high-pressure tanks and transported to a network of filling stations for use by hydrogen-powered trucks, buses and cars.

Our mission

STÖHR is committed to having a positive impact on the environment and offers solutions for hydrogen-based transportation systems at all medium temperatures, valve sizes and pressure levels for both on-road mobile applications and stationary use at filling stations. Get in touch to discuss your design concept and we’ll work with you to design, prototype and manufacture the fittings and installations you need for mass production. We’re open to your challenge!

STÖHR hydrogen valves – best for:

- Supply line from LH2 tank to fuel cell

- Mobile tank shut-off valves with TPED certificate actuated by handwheel, electric or pneumatic drive.

- Stationary tank shut-off with electric, pneumatic or hydraulic actuation and check valves.

- Hydrogen truck trailers.

- Buffer storage for green energy.

Our hydrogen valve series

Fittings best for Automotive

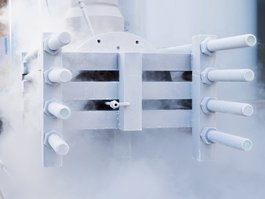

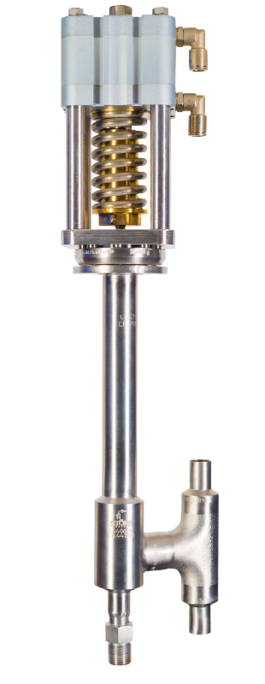

Sticks 900

example for supply line from LH2 tank to fuel cell

Essential product features:

- Easy replacement of the compatible valve inserts

- Prepared for installation into vacuum-jacketed lines

- Cryogenic valve and filter series consisting of globe or control valve and filter

- Cryogenic valve for media temperatures ranging from 2K to 243K (-271° C to -30° C)

- Available as straight body type (standard) or in angle version (optional)

- Low heat input through optimised bodies

- As control valve, high control accuracy for flow control

- Space-saving installation (small footprint) using compact actuators

- For control valves, IP-controller mounted on top of the actuator

- Installation position can be horizontal or even upside down (optional: series 900 TD)

- Nominal sizes: DN15 / DN25 / DN50

- Nominal pressure: PN 10 / 18 / 25 depending on size

www.stoehr-valves.de/en/sticks900

All features technical data and sizes

Cryogenic pneumatic globe valve

Cryogenic pneumatic globe valve with integrated check function

Cryogenic filter

STÖHR hydrogen valves for:

production | transportation | storage | filling | usage

STÖHR ARAMATUREN stand for

- Fittings for gases since 1938

- Experienced in cryogenics since the 1960s

- Quality system based on ISO 9001:2015

- High product safety in operation

- High product reliability, low maintenance

- Long durability

- Designed and Made in Germany

- High leak tightness to the environment

- Lowest heat loads to the medium

- Highest pressure levels

- Applicable at cryogenic, ambient and even hot medium temperatures

- For all environmental and service conditions

- Upstream, midstream and downstream applications

Download

Valve leaflet

Also interested in valves for green energy for:

infrastructure, aeronautics, ships, yachts, ferries or railroad technology

Are you interested in valves from STÖHR ARMATUREN for other stationary or mobile hydrogen apllications for Infrastructure, Aeronautics, Martime (ships, yachts, ferries) or Railroad technology?

Do not hesitate to follow the appropriate link below, or contact us.

We look forward to meeting you.